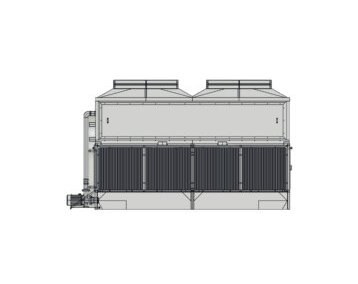

HBR Series - MITA Hybrid coolers.

With HBR series you can work in free cooling: the fluid circulates inside a tube evaporator coil. HBR is able to operate in evaporative (wet) or dry (dry) mode depending on the external temperature or the fluid to be cooled. HBR is a hybrid system designed to reduce water consumption and/or energy consumption.

– Axial motor-fan with direct coupling, low installed power, low noise levels.

– Motors with IP56 protection.

– Tower body made of 22 mm thick fibreglass sandwich panels.

– Support structure in hot dip galvanized steel after fabrication (galvanization process in accordance with UNI EN ISO 1461-99 standard, thickness not inferior to 80 microns).

– Distribution system in PVC equipped with wide non-clogging PP spray nozzles.

– Certified PP drift eliminators (entrainment 0.01%).

– Heat exchanger coils made of smooth tubes in hot dip galvanized steel after fabrication (MCC series).

– Finned coils made of copper and aluminium (HBR series).

– Tank with sloping base entirely made of fibreglass.

– Each machine can be equipped with accesses for inspections and maintenance of internal parts.

– Capacity: from 80 kW to 1.7MW (indicative capacity referring to a machine, thermal gradient 5°C).

LOAD BEARING STRUCTURE in high thickness, hot dip galvanised steel (galvanisation process in accordance with UNI EN ISO 1461-99 standard, thickness not inferior to 80 micron).

CASING consisting of 22 mm thick polyester resin sandwich panels reinforced with fibreglass with gelcoat for UV-protection.

Sealing between the load bearing structure and the panels is guaranteed by a special bituminous sealing gasket.

In order to access the internal cooling coil, it is possible to equip the unit with totally removable walls (located on the long sides).

NUTS AND BOLTS in stainless steel AISI 304.

COOLING COIL/S consisting of high quality steel tubes, fitted into a support frame made of steel profiles: the whole assembly is hot-dip galvanised after fabrication.

During manufacture every single circuit is carefully checked and tested. The slope of the tubes ensures the complete discharge of the fluid and the outlet connections are placed in line with the bottom of the outlet header to avoid “dead zones”.

FINNED TUBES COIL/S in copper and aluminium

FAN DECK/S depending on the model and on the version:

- Entirely in FRP, adequately structured and reinforced, with gelcoat for UV-protection.

- In non-slip stretched metal sheet, walkable, hot dip galvanized after fabrication

- Every fan deck is equipped with an adequately sized fan ring, in FRP or galvanized metal sheet, with such a shape as to minimise vortex and air pressure drops. The axial fan, directly coupled with the electric motor, is located inside the ring.

AXIAL FAN SYSTEM (reversible fan/s) made of:

- One or more hot-dip galvanised steel after fabrication motor support7s

- Low rpm axial fan/s with blades in plastic material connected to central aluminium hub directly coupled to the motor

- One or more three-phase electric motor/s, sealed execution (IP56), without ventilation, with back closing shield, multi-voltage (230/400 – 400/690 V) and multi-frequency (50-60 Hz), with tropicalized windings, class F insulation

FAN PROTECTION GRID in stainless steel AISI 304

ELECTRICAL ISOLATOR (lockable), located on the tower casing, for emergency stops, box IP65

DRIFT ELIMINATORS, high efficient, certified by EUROVENT, consisting of three folds PP sheets, thermoformed under vacuum and welded together to form panels of such shape and size as to guarantee maximum efficiency of droplet separation from the airflow drawn by the fan.

WATER DISTRIBUTION SYSTEM made of PVC pipes and connectors complete with flanged connection, entirely made of plastic material, consisting in a main header and branches with non-clogging, spray nozzles.

This system grants a perfect and even perfusion of the coil, and therefore an optimal performance.

The non-clogging nozzles are made of isotactic polypropylene with full cone (120° angle) spraying.

WATER RECIRCULATION PUMP for the spray-water of the evaporative cooling circuit, connected by a PVC piping to the water distribution system, external to the coil and the basin.

WATER COLLECTION BASIN entirely in fibreglass reinforced polyester (FRP), equipped as standard with a sloping base with rounded corners for easy cleaning operations, complete with water, drain, make-up and overflow connections.

The basin is a separate component which is fixed to a hot-dip galvanised steel after fabrication frame, which includes the removable FRP louvers.

All models are available in the following special versions:

SILENT/SUPER SILENT – different technical solutions to reduce the noise

INOX – heat exchanger coils available in stainless steel

Inquiry

Niezwłocznie po wpłynięciu do nas zapytania zostanie przygotowana dla Państwa oferta wraz ze szczegółową wyceną.