S222 dual circiut brazed plate heat exchanger

ONDA is a leading company in Heat Exchange, partner of all main Chiller manufacturers. ONDA produces a complete range of Shell & Tube and Brazed Plate Heat Exchangers dedicated to Refrigeration and Air Conditioning. Our evaporators and condensers are available with different raw materials and well adapted to different refrigerants (R22, R134a, R410A…) from 3 to 850 Tons. All our products are manufactured under ISO 9001 with all the main worldwide certifications: ASME, GOST, GL, PED, RINA, UL.

| Technical Information | |

| The main applications of our brazed plate heat exchangers are the evaporation and the condensation of the refrigerant gas in the air conditioning and refrigeration plants, the hot water production in heat pumps, the heat recovery. Suitable refrigerants are all HCFCs, HFCs and others, unless they are compatible with the manufacturing materials. |

|

| Materials | |

| The top quality materials used to manufacture the ONDA brazed plate heat exchangers satisfy the requirements of the 97/23/EC Directive (Pressure Equipment Directive). The type construction of the brazed plate heat exchangers consists of: |

|

|

|

|

|||||

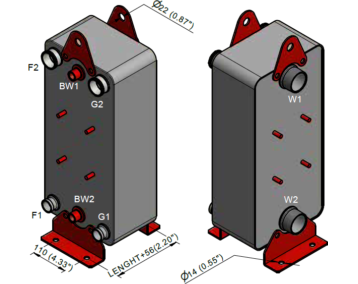

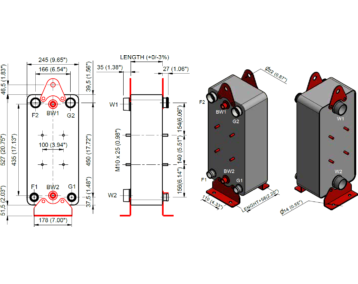

| F1 | INLET | Refrigerant Circuit 1 | F2 | OUTLET | Refrigerant Circuit 1 |

| G1 | INLET | Refrigerant Circuit 2 | G2 | OUTLET | Refrigerant Circuit 2 |

| W1 | INLET | Secondary Fluid | W2 | OUTLET | Secondary Fluid |

| BW1 – BW2 | Connections for Sensor | ||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

| N – Number of plates | ||

| Letter to Identify Connections Type | ||

| S – Soldering Connections C – Conical Male Gas Threaded Connections G – Cylindric Male Gas Threaded Connections F – Female Gas Threaded Connections V-BV – Grooved System for Standard Flexible Coupling R – Rotalock Connections Male |

||

| PLATE HEAT EXCHANGER MATERIAL | Stainless Steel 316L | Thickness 0.35 mm |

| BRAZING MATERIAL | Copper (Cu) | |

|

|||||

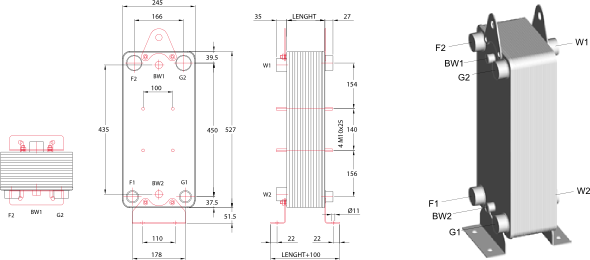

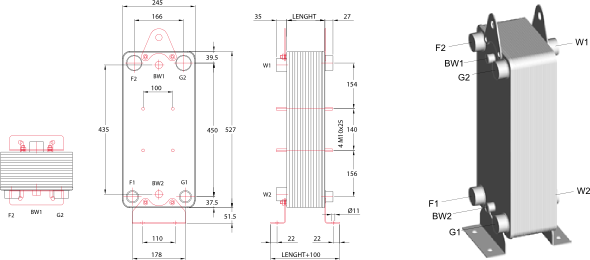

| F1 | INLET | Refrigerant Circuit 1 | F2 | OUTLET | Refrigerant Circuit 1 |

| G1 | INLET | Refrigerant Circuit 2 | G2 | OUTLET | Refrigerant Circuit 2 |

| W1 | INLET | Secondary Fluid | W2 | OUTLET | Secondary Fluid |

| BW1 – BW2 | Connections for Sensor | ||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

| N – Number of plates | ||

| Letter to Identify Connections Type | ||

| S – Soldering Connections C – Conical Male Gas Threaded Connections G – Cylindric Male Gas Threaded Connections F – Female Gas Threaded Connections V-BV – Grooved System for Standard Flexible Coupling R – Rotalock Connections Male |

||

| PLATE HEAT EXCHANGER MATERIAL | Stainless Steel 316L | Thickness 0.35 mm |

| BRAZING MATERIAL | Copper (Cu) | |

Inquiry

Niezwłocznie po wpłynięciu do nas zapytania zostanie przygotowana dla Państwa oferta wraz ze szczegółową wyceną.