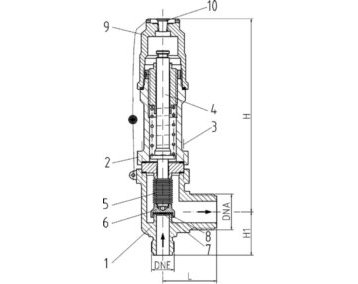

Parker-Herl T21.1FA Safety Overflow Valve DN12

Safety valves are type tested for gas, vapour and liquid within a pressure range from 6 to 40 bar. (Please indicate required set pressure!) The safety overflow valve is equipped with a back-pressure compensating bellows-seal. It will open independently against 90% back pr essure once the set pressure is reached.

The safety overflow valve is also suitable for pressure decrease in case of thermal expansion because even if the back pressure is higher, the valve will still open and blow the arising amount of throttled saturated vapour of f. * To comply with the requirements of EN 4126, part 5.1.8 the cap has a G1/4“ bore for installation of a control over the bellows-seal efficiency. This will allow safety measures (e.g. safety valve replacement) at once when pressure independency is lost by bellows-sealdefect. Approvals through TÜV, GOSGORTECHNADSOR, GOST (other approvals on request) .

Product features:

- Back pressure in dependent • Suitable for refrigerants acc. to: EN 378-1 (annex E). •

- Medium temperature -50°C to +120°C • Design: DIN EN 12284, EN 13136, EN ISO 4126 •

- Length: HERL-Standard

- Connections: G1/2” inlet, G1” outlet • Conformity to Pressure Equipment Directive 2014/68/E

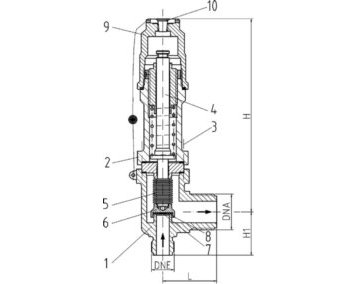

The safety overflow valve is also suitable for pressure decrease in case of thermal expansion because even if the back pressure is higher, the valve will still open and blow the arising amount of throttled saturated vapour of f. * To comply with the requirements of EN 4126, part 5.1.8 the cap has a G1/4“ bore for installation of a control over the bellows-seal efficiency. This will allow safety measures (e.g. safety valve replacement) at once when pressure independency is lost by bellows-sealdefect. Approvals through TÜV, GOSGORTECHNADSOR, GOST (other approvals on request) .

Product features:

- Back pressure in dependent • Suitable for refrigerants acc. to: EN 378-1 (annex E). •

- Medium temperature -50°C to +120°C • Design: DIN EN 12284, EN 13136, EN ISO 4126 •

- Length: HERL-Standard

- Connections: G1/2” inlet, G1” outlet • Conformity to Pressure Equipment Directive 2014/68/E

The safety overflow valve is also suitable for pressure decrease in case of thermal expansion because even if the back pressure is higher, the valve will still open and blow the arising amount of throttled saturated vapour of f. * To comply with the requirements of EN 4126, part 5.1.8 the cap has a G1/4“ bore for installation of a control over the bellows-seal efficiency. This will allow safety measures (e.g. safety valve replacement) at once when pressure independency is lost by bellows-sealdefect. Approvals through TÜV, GOSGORTECHNADSOR, GOST (other approvals on request) .

Product features:

- Back pressure in dependent • Suitable for refrigerants acc. to: EN 378-1 (annex E). •

- Medium temperature -50°C to +120°C • Design: DIN EN 12284, EN 13136, EN ISO 4126 •

- Length: HERL-Standard

- Connections: G1/2” inlet, G1” outlet • Conformity to Pressure Equipment Directive 2014/68/E

Inquiry

Niezwłocznie po wpłynięciu do nas zapytania zostanie przygotowana dla Państwa oferta wraz ze szczegółową wyceną.