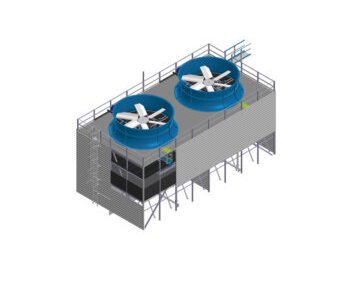

PU Series- MITA Open circuit field-erected towers

The PU series is suggested for large size plants: for this reason, this range of towers is field-erected (components to be assembled on site).

The structure is made up of protruded FRP profiles, minimizing the presence of metal elements. Each single cell is able to cool water flow rates up to 5,500 m3/hr. The design and the types of materials used are optimal for any industrial process. Different types and configurations of heat exchange packs allow treating all types of water, regardless of their aggressiveness. The PU series is the most appropriate option when the flow to be cooled is of considerable magnitude and where the cost of transport (distance and volume of the components to be moved) can have a substantial impact.

– Structure entirely made of protruded FRP profiles: calculated to support static and dynamic loads, seismic factors, wind thrust, snow load, etc.

– External covering system in corrugated panels of flame retardant fibreglass.

– Fibreglass diffusers (FRP).

– Each machine can be equipped with various accesses, for simple inspections and maintenance to: motor-fan group, plenum, water distribution system, droplets separators, heat exchange pack.

– Axial motor-fan with gearbox reducer, low installed power, low noise levels.

General description

Cooling towers of this series consist of:

• Structure and cladding

• Water distribution system

• Filling

• Drift eliminator

• Mechanical equipment

Accessibility

The upper part of the tower consists of a hot dip galvanized steel deck. An inspection trap and an internal ladder (one by each cell) in order to allow the access to the interior of the tower are included, as well as a peripheral handrail. To reach the upper part, a ladder from the floor is available.

Air entry

At the air intake in the lower part of the tower, optionally, several louvers are placed with the double object of conducting air inlet and avoiding water splash out of the tower.

Filling

These cooling towers can incorporate different filling types according to water quality features:

• Laminar: clean and industrial waters. It is composed by plastic panels with flute size from 12 to 40 mm and highly efficient.

• Semi-splash: composed by hollow cylinders vertically installed. Ideal for waters in which the content of suspended solids is high.

• Splash: it is recommended for those cases in which the content of suspended solids is extremely high. This film is composed of L-shaped plastic splash bars placed horizontally and supported by vertical stainless steel meshes, allowing large passages for water and air, thus avoiding the possibility of clogging.

Water distribution system

• FRP open channels or plastic pipes, both systems trough gravity nozzles and impingement plates.

Inquiry

Niezwłocznie po wpłynięciu do nas zapytania zostanie przygotowana dla Państwa oferta wraz ze szczegółową wyceną.